Welcome to the exciting world of steam engines! These fascinating machines, powered by the simple yet powerful principle of steam and pressure, have been pivotal in shaping the modern world. Whether you're a budding engineer or just looking for a fun DIY project, building a steam engine at home can be a rewarding experience. In this guide, we’ll explore the fundamentals of steam engines, their historical significance, and how you can create your own version with just a few materials. So, let’s get rolling!

Materials Needed for Your Steam Engine Project

Before diving into the actual assembly, it's essential to gather all the materials needed for building your steam engine. Below is a list of the main components, along with suggestions on where to find them and why they’re necessary for your project.

- Metal Boiler:

Your steam engine needs a boiler to generate steam. You can use a small metal container or canister, ideally made of copper or stainless steel, as these materials handle heat well. Ensure that the container can withstand high pressure; otherwise, it could be dangerous!

- Heating Element:

A reliable heat source is crucial for your boiler. You can use a small propane torch or an electric heating element. If you're looking for something more hands-on, a burner made from materials like steel can also work, but keep safety practices in mind.

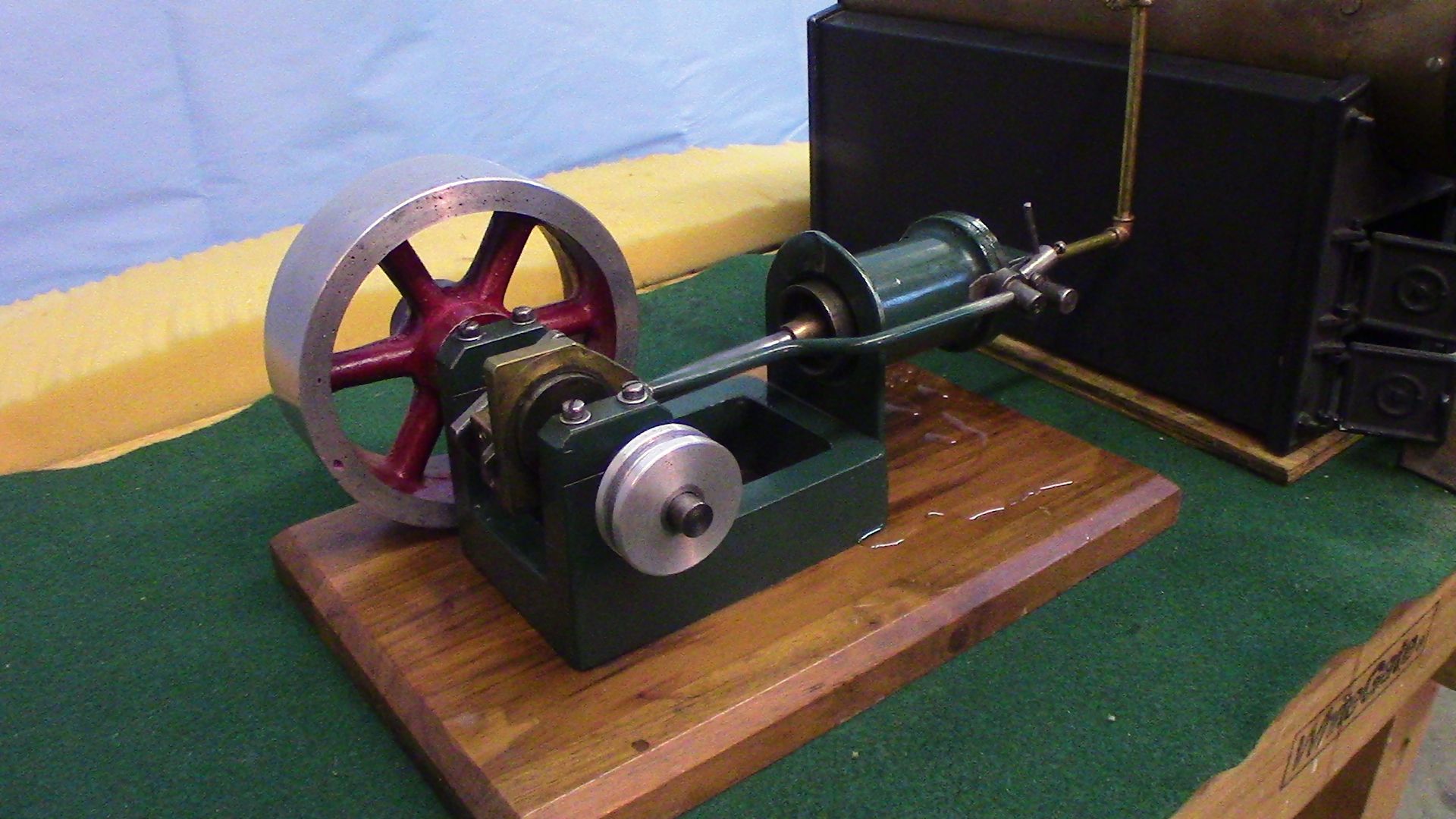

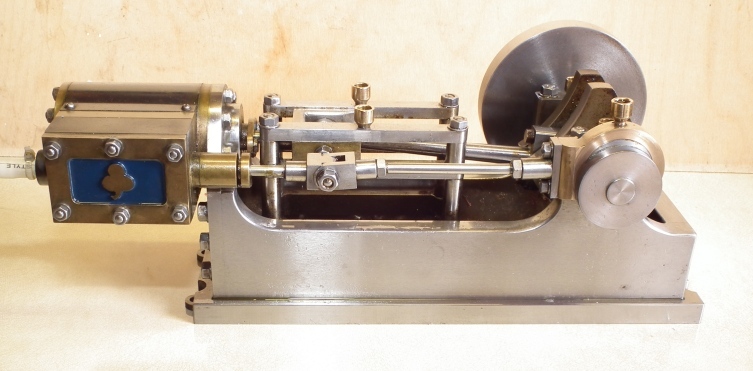

- Engine Block:

Your steam engine will require an engine block where the steam will push the piston. You can make this from metal, wood, or even heavy plastic if you're looking for a lightweight option. The essential feature is that it needs to be robust enough to handle the action of the moving piston.

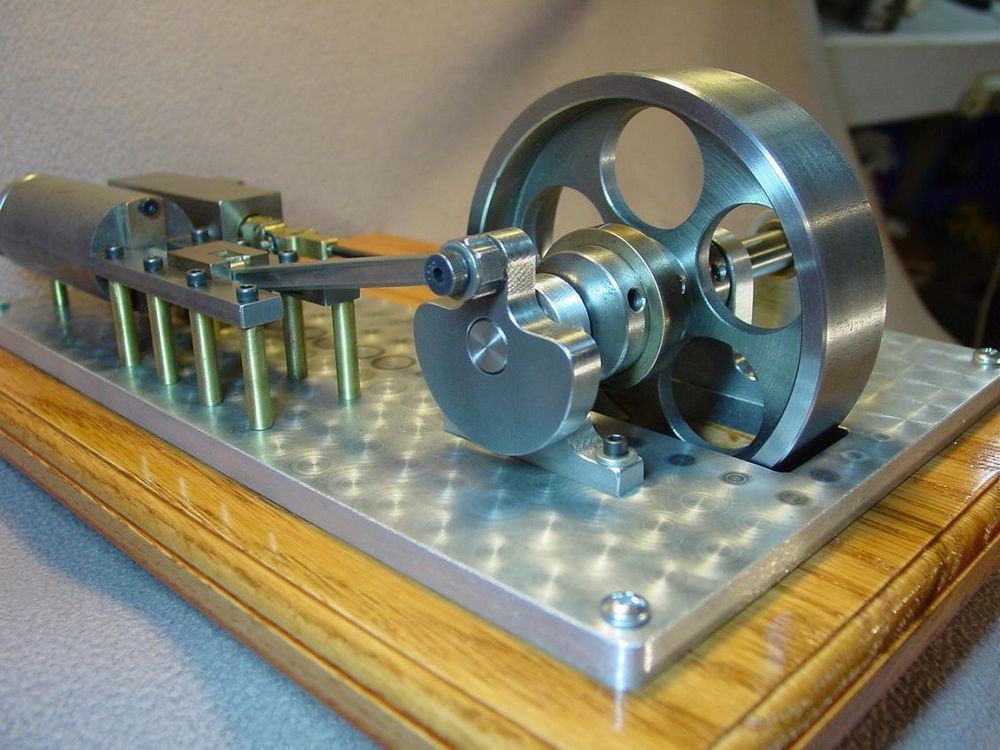

- Piston and Cylinder:

A piston is essential for converting steam energy into mechanical work. You can create a piston from a piece of metal or hard plastic that fits snugly inside a corresponding cylinder, allowing for minimal air gaps to maximize efficiency.

- Connecting Rod:

This rod connects the piston to the crank, converting linear motion into rotational motion. You can use a sturdy metal rod or even a strong wooden dowel, depending on your design.

- Flywheel:

The flywheel helps to maintain the momentum of your engine. This can be made from metal or a heavy plastic disc. It should be balanced to ensure smooth operation.

- Rubber Seals and Gaskets:

To prevent steam leaks, you’ll need high-temperature silicone gaskets or rubber seals. These will help ensure that your steam engine maintains pressure while operating.

- Miscellaneous Tools:

Lastly, you will need a few basic tools:

- Screwdriver

- Wrench

- Drill

- Saw (if cutting materials)

- Safety gear (gloves, goggles)

Gathering these materials will set the stage for a fantastic DIY project. Remember to prioritize safety, especially when working with heat and pressure. In the next sections, we’ll guide you through the step-by-step assembly of your very own steam engine. Happy building!

Also Read This: How Does "She Knows" from Enchanted Play on Dailymotion? Exploring the Song

3. Step-by-Step Instructions to Build Your Steam Engine

Building your own steam engine may seem daunting, but with the right materials and a bit of patience, it can actually be a fun and rewarding project. Here’s a straightforward step-by-step guide to help you through the process!

Materials You’ll Need:

- Copper pipes (1/2 inch diameter)

- Metal sheet (for the boiler)

- Wood (for the base)

- Pressure gauge

- Valve (for steam release)

- Piston and cylinder (can be purchased or crafted)

- Water source (like a small container)

- Heat source (propane torch or electric heater)

- Tools (wrenches, soldering iron, drill)

Step 1: Create the Boiler

Start by shaping your metal sheet into a cylindrical form for the boiler. Secure the ends using a strong adhesive or by welding them together. Ensure to create an opening for the water inlet and steam outlet.

Step 2: Assemble the Piston and Cylinder

Your piston should fit snugly within the cylinder to create a good seal. Use lubrication to ensure smooth operation. Attach the cylinder vertically above the boiler to allow steam to rise directly into it.

Step 3: Construct the Frame

Build a sturdy base using the wood. This will support the entire assembly. Make sure your base can handle the thermal expansion and weight of the steam engine components.

Step 4: Connect the Components

Use copper pipes to connect the boiler’s steam outlet to the cylinder’s inlet. Make sure there are no leaks by ensuring all joints are sealed properly. You can use a soldering iron for an airtight seal.

Step 5: Install the Pressure Gauge

Attach the pressure gauge to monitor the steam pressure. This is crucial for safety, as it lets you know when you are approaching dangerous levels.

Step 6: Add the Valve

Install a valve for steam release. This is important for releasing excess pressure safely and ensuring your engine operates efficiently.

Step 7: Testing the Engine

Fill your boiler with water and heat it with your chosen heat source. Slowly bring it to a boil, and monitor the pressure gauge. The steam should move into the cylinder and start operating the piston. If everything is set up correctly, you should see your engine coming to life!

Remember, patience is key. Each step needs to be done with precision to ensure the engine operates safely and efficiently.

Also Read This: How to Make a Barbie Cake with Dailymotion’s Creative Baking Tutorial

4. Safety Precautions When Working with Steam Engines

While building a steam engine can be an exciting project, safety should always be your top priority. Here are some essential precautions to keep you safe while working with steam:

1. Use Quality Materials

Ensure that all materials used, especially the boiler, can withstand high pressures and temperatures. Using subpar materials can lead to leaks or ruptures.

2. Wear Protective Gear

- Safety goggles to protect your eyes from flying debris.

- Heat-resistant gloves to prevent burns.

- Apron to protect your clothing and skin from hot surfaces.

3. Monitor Pressure Levels

Always keep an eye on the pressure gauge. If the pressure exceeds the safe limit, activate the steam release valve immediately to avoid dangerous situations.

4. Work in a Well-Ventilated Area

Ensure your workspace is well-ventilated. Steam and heat can build up quickly, so it's important to have good airflow to disperse any excess heat.

5. Keep Flammable Materials Away

Since you will be using a heat source, make sure any flammable materials—such as papers and cloth—are kept out of reach to avoid accidental fires.

6. Educate Yourself

Before starting, take the time to read about steam engine mechanics and safety practices. The more informed you are, the safer your building experience will be.

By following these safety precautions and being mindful of your environment, you can build your steam engine with confidence and excitement! Happy building!

Also Read This: Quick Tips on Uploading URLs on Dailymotion Using Desktop

5. Common Issues and Troubleshooting Tips

Building a steam engine can be an exhilarating project, but like any DIY endeavor, it's not without its challenges. Knowing how to tackle common issues will save you time and frustration. Here are some frequent problems you might encounter while building or running your steam engine, along with some handy troubleshooting tips.

- Leaking steam: One of the most common issues you'll face is steam escaping from joints or connections. To troubleshoot this:

- Check all joints and seals for tightness. A good way to ensure tight fittings is to use Teflon tape or pipe dope on threaded connections.

- If you find a leak, you may need to disassemble the part and reapply sealant, or consider using a new gasket.

- Insufficient pressure: If your steam engine isn’t producing enough pressure, it could be due to a few factors:

- Check your heat source. Is it strong enough to create the necessary steam? Sometimes, you may need to adjust the flame or change to a better heat source.

- Verify that your boiler is functioning properly and there are no blockages in the steam lines.

- Piston sticking: If the piston isn’t moving smoothly, it can lead to inefficient operation:

- Inspect the piston for dirt or rust. Lubricate the piston and cylinder regularly.

- Make sure tolerances are correctly maintained; there should be enough space for movement without being too loose.

- Noise issues: All engines make noise, but excessive rattling or clanking can be a sign of trouble. To address this:

- Check all screws and bolts to ensure they’re tight. Loose components can lead to unwanted vibrations.

- Consider adding rubber mounts or grommets to dampen the noise if you’re running the engine in a sensitive environment.

By keeping an eye on these issues and applying the troubleshooting tips, you can ensure that your steam engine operates more smoothly and efficiently, giving you the satisfaction of a job well done.

Also Read This: Understanding the Legality of Dailymotion in Canada

6. Enhancing Your Steam Engine: Customizations and Improvements

Once you’ve built and successfully run your steam engine, the fun doesn’t have to end there! Customizing and improving your engine can not only enhance its performance but also make it more unique to your style. Here are some ideas for upgrades and customizations.

- Add a pressure gauge: Monitoring your steam pressure can help you operate your engine safely and efficiently. Installing a gauge will allow you to keep an eye on the pressure and make necessary adjustments during operation.

- Improve the boiler: Consider upgrading to a more efficient boiler design. For example, a multi-pass boiler allows steam to pass multiple times through the heating area, improving heating efficiency.

- Custom paint job: Personalizing the look of your steam engine can give it a character that’s all your own. Pick colors that reflect your personality or theme. Just make sure to use heat-resistant paint suitable for machinery.

- Install a governor: A governor can help to regulate the speed of your engine, making it more efficient and preventing it from running away at high speeds.

- Upgrade the piston: Consider a better-quality piston made from advanced materials like brass or aluminum. These materials can reduce friction and improve the overall performance of your engine.

- Sound and lighting effects: If you're using your steam engine for a display or model, why not add sound effects or LED lights that mimic the sounds and visuals of a real steam engine? It can add educational value and a bit of fun!

These customizations not only make your steam engine more efficient but also allow you to showcase your creativity. Dive into each modification thoughtfully and enjoy the process as you enhance your creation. Get excited, because each upgrade is another chance to learn and innovate!

Conclusion and Next Steps for Steam Engine Enthusiasts

Building a steam engine at home can be a rewarding project that deepens your understanding of thermodynamics and mechanical principles. Whether you're a seasoned hobbyist or a curious beginner, the process of crafting your own steam engine offers invaluable hands-on experience. Here are a few essential next steps for those looking to continue their steam engine journey:

- Research Advanced Designs: Explore more complex steam engine models to enhance your skills. Consider designs like the double-acting engine or compound engine.

- Experiment with Materials: As you gain confidence, try using different metals and plastics to see how they affect engine performance.

- Join a Community: Engage with online forums, local clubs, or maker spaces. Connecting with other steam engine enthusiasts can provide support and inspiration.

- Attend Workshops: Look for workshops or classes in your area that focus on model building or steam technology.

- Document Your Progress: Keep a project journal or blog about your steam engine journey. Sharing your experiences can help others and enhance your learning.

Finally, always ensure safety precautions are in place while experimenting with steam power. From using appropriate materials to protective gear, a cautious approach will make your DIY experience enjoyable and safe. Happy building, and may your passion for steam engines propel you into exciting new projects!

admin

admin