Dairy Milk Chocolate is a beloved treat enjoyed by millions around the world. But have you ever wondered how this creamy delight is crafted in a factory? The journey from raw ingredients to that smooth, irresistible bar involves a fascinating process that combines science with artistry. In this blog post, we’ll delve into the intricate steps of Dairy Milk Chocolate production, exploring everything from ingredient selection to the final packaging. Let’s unwrap the secrets behind this iconic chocolate!

The Ingredients of Dairy Milk Chocolate

To understand how Dairy Milk Chocolate is made, we first need to look at its key ingredients. Each component plays a crucial role in creating that distinct creamy flavor and texture. Here’s a breakdown of the primary ingredients:

- Cocoa Solids: This is where the chocolate flavor originates. Cocoa solids are derived from fermented, roasted cocoa beans, which are ground into cocoa mass.

- Cocoa Butter: This fat extracted from cocoa beans gives Dairy Milk its smooth texture. It also enhances the chocolate’s melting quality.

- Milk Powder: The star of Dairy Milk! This powder adds creaminess and sweetness, making the chocolate softer and richer.

- Sugar: Essential for sweetness, sugar balances the bitterness of cocoa solids, creating that delightful flavor profile.

- Emulsifiers: Ingredients like lecithin help blend the cocoa and milk, ensuring a uniform texture. This is vital for a consistent taste.

Here’s a quick table summarizing the ingredients:

| Ingredient | Function |

|---|---|

| Cocoa Solids | Provides chocolate flavor |

| Cocoa Butter | Creates a smooth texture |

| Milk Powder | Adds creaminess |

| Sugar | Balances bitterness |

| Emulsifiers | Ensures uniform texture |

By carefully selecting and blending these ingredients, manufacturers create the beloved Dairy Milk Chocolate that we all enjoy. Each bar is a perfect harmony of flavors, delivering a sweet, creamy experience with every bite!

Also Read This: Why AdBlock Fails on YouTube and How to Resolve It

The Chocolate Production Process

Making Dairy Milk chocolate is a delightful journey that transforms raw ingredients into the sweet treat we all love. The process begins with sourcing high-quality cocoa beans, which are the heart of any chocolate. Here’s a quick overview of the steps involved:

- Cocoa Bean Harvesting: Farmers handpick ripe cocoa pods, which are then opened to extract the cocoa beans.

- Fermentation: The beans are placed in shallow containers and covered with banana leaves, where they ferment for several days. This step enhances the beans' flavor.

- Drying: After fermentation, the beans are spread out under the sun to dry, reducing their moisture content.

- Roasting: Dried beans are roasted to bring out rich flavors. The duration and temperature can vary based on the desired taste profiles.

- Cracking and Winnowing: Roasted beans are cracked, and the outer shells are removed, leaving behind cocoa nibs, which will be ground into cocoa mass.

- Grinding: The nibs are finely ground, creating cocoa liquor, which is a combination of cocoa solids and cocoa butter.

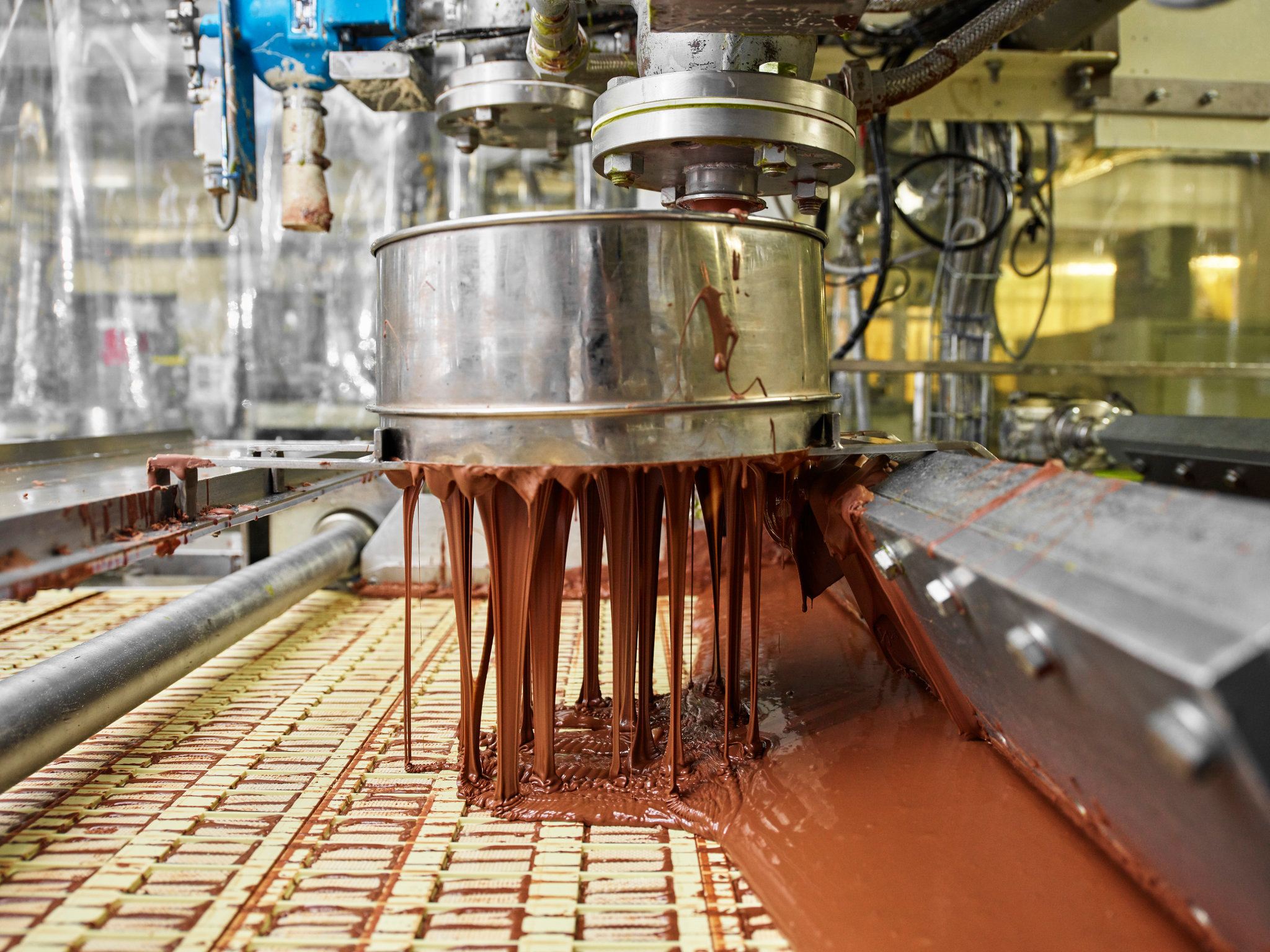

- Mixing: For Dairy Milk chocolate, milk powder and sugar are combined with the cocoa liquor. This mixture is blended thoroughly to achieve a silky texture.

- Conching: The chocolate mixture is continuously mixed and aerated, refining its texture and enhancing flavor.

- Tempering: The chocolate is cooled and reheated to stabilize the cocoa butter, ensuring a shiny finish and a satisfying snap.

- Molding and Cooling: Lastly, the tempered chocolate is poured into molds and cooled, solidifying into the familiar bars.

And there you have it! A delicious piece of Dairy Milk chocolate ready to be enjoyed!

Also Read This: Step-by-Step Swimming Techniques for Deep Water on Dailymotion

Quality Control in Dairy Milk Chocolate Manufacturing

Quality control is essential in the production of Dairy Milk chocolate to ensure consistency, safety, and taste. Here’s how manufacturers maintain high standards:

- Ingredient Inspection: Every batch of cocoa beans, milk powder, and sugar is inspected for quality before production. This includes checking for freshness and flavor.

- Process Monitoring: Throughout the chocolate-making process, various parameters such as temperature and humidity are closely monitored. This ensures that each step meets the required standards.

- Sampling and Testing: Regular samples of chocolate are taken during production for taste tests and texture analysis. This helps in maintaining flavor consistency.

- Hygiene Practices: Strict hygiene practices are enforced in the factory. Employees are trained to follow sanitation protocols, and regular audits are conducted.

- Packaging Quality: Once the chocolate is molded, the packaging is also inspected for integrity and aesthetics to ensure it meets brand standards.

- Consumer Feedback: Feedback from consumers plays a critical role. Manufacturers often conduct surveys to gather insights on taste and quality, allowing them to make necessary adjustments.

By adhering to these rigorous quality control measures, Dairy Milk chocolate remains a beloved treat that everyone can enjoy with confidence!

Also Read This: Exploring Dailymotion’s Explicit Content Settings and Family Filters

5. Packaging and Distribution of Dairy Milk Chocolate

Once the Dairy Milk chocolate is crafted to perfection, it’s time to think about how to get it into the eager hands of chocolate lovers everywhere. Packaging is a critical step in this process. The chocolate bars are first cooled and then wrapped in protective layers to maintain freshness and prevent damage during transportation.

Here's how the packaging process generally unfolds:

- Cooling: Before packaging, the chocolate is cooled in a controlled environment to solidify and stabilize.

- Wrapping: Each bar is wrapped in foil to protect it from moisture and light, which can affect flavor and texture.

- Branding: Afterward, colorful outer packaging is printed with the iconic Dairy Milk branding, nutritional information, and ingredients.

- Quality Control: Before distribution, quality checks are made to ensure that every bar meets the company’s high standards.

Once packaged, the chocolate is ready for distribution. It’s loaded onto trucks and sent to various retailers worldwide. Whether it’s a local grocery store, a specialty candy shop, or an online marketplace, Dairy Milk is designed to be accessible to everyone. The logistics of distribution involve careful planning to ensure that the chocolates arrive fresh and in perfect condition, ready to delight consumers.

6. Conclusion: The Journey of Dairy Milk Chocolate

The journey of Dairy Milk chocolate is nothing short of fascinating. It begins with the careful selection of quality ingredients like cocoa beans and milk, followed by the intricate blending and conching processes that create its signature smooth texture. Each step, from tempering to molding, plays a significant role in crafting a chocolate that has won the hearts of many.

After production, the careful packaging and distribution ensure that this beloved treat reaches consumers in the best condition possible. Dairy Milk chocolate isn’t just a product; it’s a delightful experience that combines craftsmanship, quality ingredients, and a touch of magic.

So, whether you're savoring a piece after a long day or sharing it with friends, remember that each bite of Dairy Milk chocolate is the result of a meticulous journey, crafted with care and passion. Next time you unwrap a bar, you can appreciate the story behind it—a tale of dedication, innovation, and an enduring love for chocolate!

admin

admin