Welcome to the fascinating world of DC motors! If you’ve ever wondered how those little electric machines spin and power various devices, you’re in the right place. DC motors, or direct current motors, are commonly found in everything from toys to electric vehicles. They convert electrical energy into mechanical energy, making them incredibly versatile and essential in today’s technology-driven world. In this post, we’ll break down the basics of how they work and explore their key components. So, whether you’re a curious beginner or a tech enthusiast, let’s dive into the mechanics of DC motors!

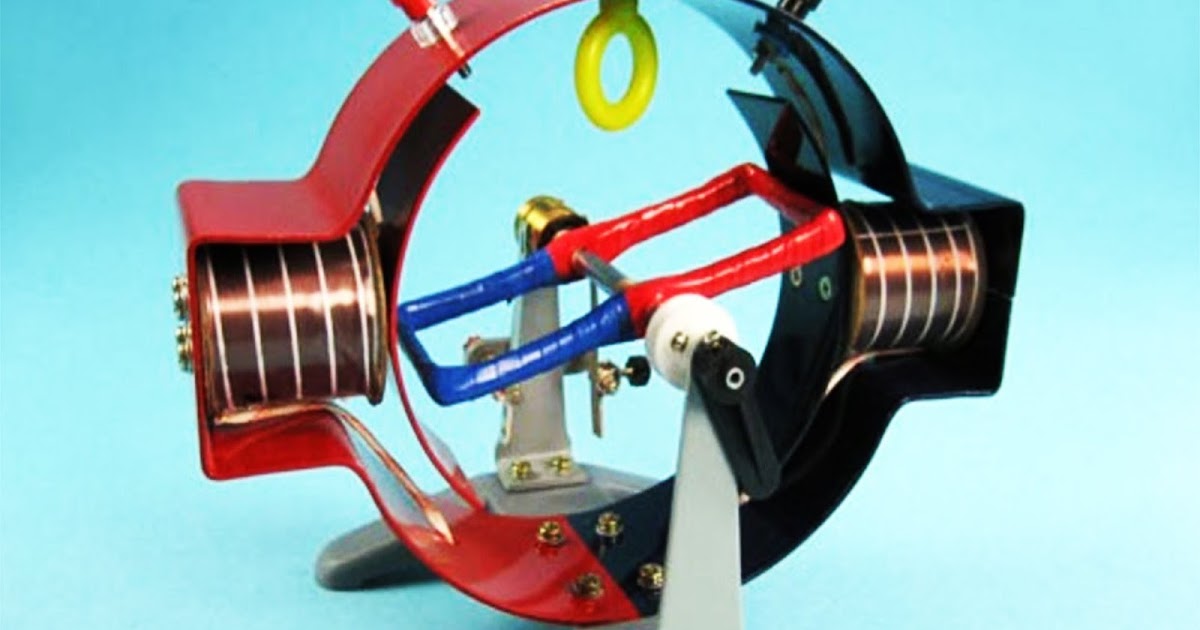

Components of a DC Motor

Understanding the components of a DC motor is crucial to grasping how it operates. Each part plays a specific role that contributes to the motor's overall functionality. Let’s take a closer look at these essential components:

- Stator: The static part of the motor, typically consisting of permanent magnets or windings that create a magnetic field.

- Rotor: Also known as the armature, this part rotates and has conductors wound around it, which interact with the magnetic field produced by the stator.

- Commutator: This component is crucial for reversing the current direction in the rotor windings. It ensures that the rotor keeps spinning in one direction by providing a continuous electrical connection.

- Brushes: Made of carbon or metal, brushes maintain contact with the commutator and deliver current to the rotor. They wear down over time, so they need occasional replacement.

- Shaft: The shaft is attached to the rotor and transfers the mechanical energy produced by the motor to the output device, such as a fan or a wheel.

Each of these components works in harmony to provide the motion you see in various machines. The interaction between the rotor and the magnetic field is what causes the rotor to turn, creating the mechanical energy needed for countless applications. Understanding these components gives you better insight into how DC motors function both in simple devices and complex systems.

Also Read This: Does Dailymotion Support OGG Video Files for Uploading and Viewing

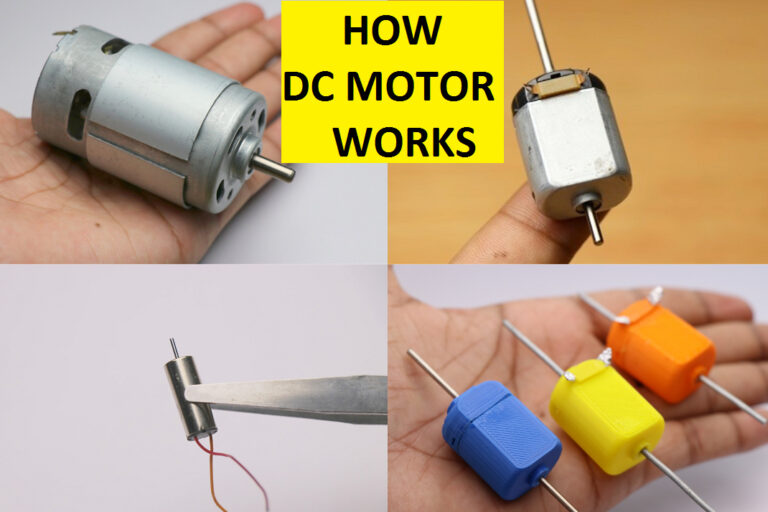

Working Principle of DC Motors

Understanding how a DC motor works can be quite fascinating! At its core, a DC motor operates based on the fundamental principles of electromagnetism. When you apply direct current (DC) to the motor, it generates a magnetic field that interacts with the magnetic field created by permanent magnets or electromagnets inside the motor.

Here's a simple way to visualize the working principle:

- *Electric Current Flow: When the motor is powered, electrical energy from the DC source flows through the armature (the rotating part of the motor).

- Magnetic Interaction: The flow of current creates a magnetic field around the armature that interacts with the magnetic field of the stationary part of the motor.

- Torque Generation: This interaction produces a force on the armature, converting electrical energy into mechanical energy, which creates torque and causes the armature to rotate.

- Commutation*: As the armature turns, a component called the commutator switches the direction of the current in the armature windings, ensuring that the torque continues to push the motor in the same direction.

The efficiency of a DC motor relies heavily on the strength of the magnetic fields, the current flowing through the armature, and the design of the motor. Simple yet effective, this principle has paved the way for countless applications, from toys to industrial machinery!

Also Read This: Creative Ways to Explore Nostalgic Animated Content Through Dailymotion

Types of DC Motors

DC motors come in various styles and designs, each tailored to specific applications and requirements. Understanding the types of DC motors is crucial for selecting the right one for your project. Let’s break down the main types:

| Type of DC Motor | Description | Common Applications |

|---|---|---|

| Brushed DC Motor | These motors use brushes to deliver current to the armature. They are simple in design and provide good torque at low speeds. | Power tools, toys, and automotive applications. |

| Brushless DC Motor | Brushless motors eliminate the need for brushes, allowing for higher efficiency and lower maintenance. They use electronic controllers for commutation. | Computer hard drives, drones, and electric vehicles. |

| Series DC Motor | In these motors, the armature and field windings are connected in series. They provide high starting torque and are great for applications requiring speed control. | Electric traction and cranes. |

| Shunt DC Motor | Here, the field winding is connected in parallel to the armature. They have stable speed characteristics and good speed regulation. | Fans, blowers, and various industrial machinery. |

| Compound DC Motor | This motor combines characteristics of both series and shunt motors, offering high starting torque and good speed regulation. It can be configured in various ways depending on the application. | Heavy-duty applications like elevators and presses. |

Each type of DC motor has its unique strengths and weaknesses, so it's important to choose one that meets the specific requirements of your project!

Also Read This: DIY Lava Cake Step-by-Step Guide on Dailymotion

Applications of DC Motors

DC motors are not just fascinating pieces of technology; they are also incredibly versatile and find applications in a wide range of industries. Here’s a quick look at some common uses:

- Automobiles: DC motors are integral to electric windows, windshield wipers, and even power seats in cars. They provide simple, reliable, and efficient motion in these applications.

- Robotics: In the world of robotics, DC motors play a crucial role. They are often used in actuators, servo systems, and for driving wheels, making robots move smoothly in their environment.

- Home Appliances: From electric shavers to power tools, DC motors are found in numerous home appliances. Their ability to provide variable speed control makes them a great choice for devices that require precision.

- Industrial Equipment: In factories, DC motors power conveyor belts, pumps, and other machinery. Their robustness and reliability make them essential for heavy-duty industrial applications.

- Aerospace: DC motors are utilized in various aerospace applications, including actuators for controlling flaps and stabilizers. Their weight-to-power ratio is ideal for flight applications.

In addition to the above, the flexibility in the design of DC motors allows for custom solutions tailored to specific needs—making them invaluable across multiple sectors. In summary, understanding the diverse applications of DC motors gives us a better insight into their importance and the role they play in technology and industry today.

Conclusion

In wrapping up our exploration of how a DC motor works, it’s clear that this simple yet powerful device has a significant impact on both everyday life and advanced technology. By converting electrical energy into mechanical energy, DC motors have paved the way for innovation across many fields.

They provide:

- Simplicity: They are relatively easy to control and integrate into existing systems.

- Flexibility: With the ability to adjust speed and direction, DC motors can be adapted for various tasks.

- Efficiency: Many modern DC motors are designed for optimal performance, minimizing energy wastage.

As technology continues to advance, the role of DC motors is likely to evolve, incorporating newer materials and methods to enhance their efficiency and effectiveness. Whether it’s in a robotic arm or your favorite home gadget, DC motors will inevitably be at the forefront of mechanical innovation.

In essence, DC motors are the unsung heroes of modern machines, and understanding how they work not only enhances our knowledge of technology but also opens the door to further innovations. Thanks for tagging along on this exploration of the fascinating world of DC motors!

admin

admin