Building your own electric fan can be an incredibly satisfying and useful DIY project! Whether you're looking to save money, customize your appliance, or simply enjoy the hands-on experience, this guide will help you through the entire process. From selecting the right materials to assembling the fan, we'll cover everything you need to know. So roll up your sleeves and let’s get started on a project that’s as practical as it is fun!

Materials Needed

Before diving in, it’s important to gather all the materials you’ll need for building your electric fan. Having everything ready will streamline your process and make the experience enjoyable. Here’s a comprehensive list of materials you’ll require:

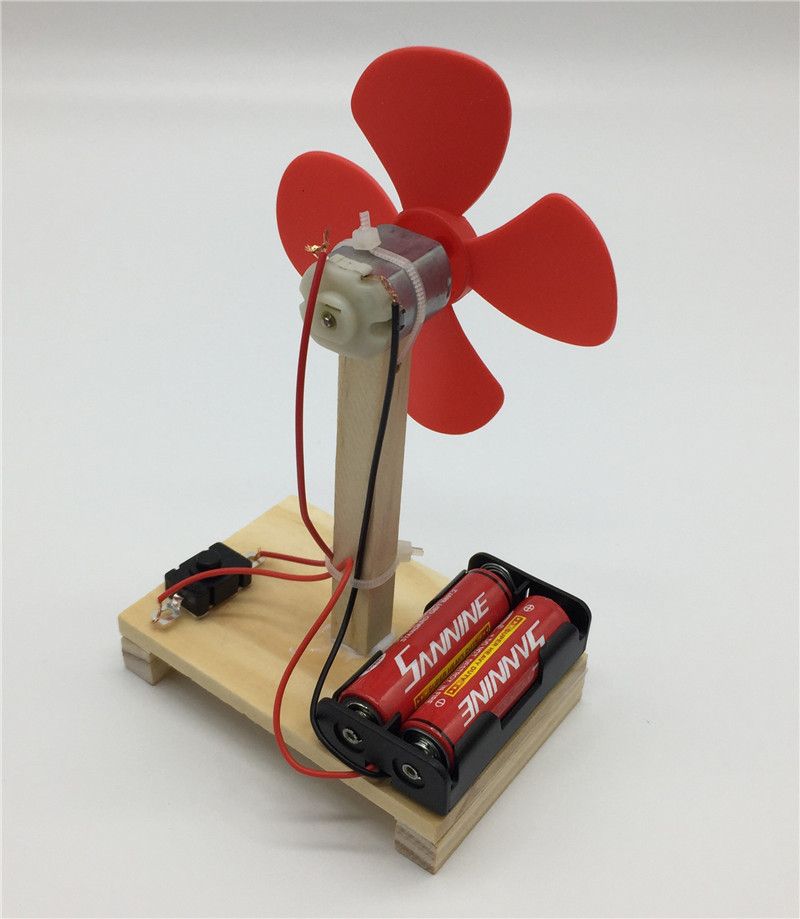

- Electric Motor: A small DC motor will work perfectly for your fan. Aim for a motor that runs at 12 volts for optimum performance.

- Fan Blades: You can either purchase ready-made fan blades or make your own from lightweight plastic or cardboard.

- Power Source: Consider a battery pack or a power adapter, depending on how you want to power your fan.

- Wire: Use insulated copper wire for the connections. You’ll need a few lengths to connect different components.

- Switch: A simple toggle switch will allow you to turn your fan on and off easily.

- Base or Stand: This can be made from wood, plastic, or even metal, depending on your design preferences.

- Tools: You’ll need basic tools such as a soldering iron, screwdriver, wire cutter, and pliers.

Optional materials could include paint or decorative elements to customize the look of your fan. With everything ready, you’re all set to bring your creative vision to life!

3. Tools Required

Alright, let’s dive into the tools you’ll need to build your very own electric fan. Having the right tools is essential to make the process efficient and enjoyable. Here’s a handy list to get you started:

- Screwdriver Set: A basic set with both flathead and Phillips screwdrivers will be perfect for assembling the fan components.

- Wire Strippers: These are crucial for stripping the insulation off the wires, ensuring that you can make the necessary connections without any fuss.

- Drill: If your fan design requires any holes or adjustments, a drill will come in pretty handy.

- Multimeter: A great tool for measuring voltage and current, ensuring everything is functioning correctly.

- Soldering Iron: If you're feeling a bit adventurous, soldering the connections can provide a more permanent solution compared to twisting wires together.

- Wire Connectors: For those who prefer simplicity, wire connectors can make the electrical connections easier and safer.

- Measuring Tape: It helps you get precise measurements for your fan assembly, especially if you’re working with wooden frames or custom sizes.

- Safety Gear: Last but not least, protect yourself! Safety goggles and gloves are vital to keep you safe while working with tools.

So gather these tools before you begin! Having everything at your fingertips will make the building process much smoother and more enjoyable.

4. Step 1: Understanding the Fan Components

Before we get our hands dirty building the fan, it's super important to familiarize ourselves with the components we'll be working with. Understanding these parts will make assembly much easier and will help you troubleshoot issues later on. Here’s a breakdown of the essential components:

| Component | Description |

|---|---|

| Motor: | The heart of your fan, the motor spins the blades to create airflow. Pick a motor with the right voltage for your fan design. |

| Fan Blades: | These are what actually move the air. You can choose from various materials and designs, depending on how powerful you want your fan to be. |

| Base: | The sturdy foundation that holds everything together. You can make it from wood, plastic, or metal; just make sure it’s stable and safe. |

| Switch: | This allows you to control the fan's speed and power. Make sure to choose a switch that can handle the motor's current. |

| Power Supply: | Decide whether you’ll use batteries or plug it into an outlet. Ensure the power supply matches the motor's voltage requirements. |

By knowing these components, you’ll have a clearer picture of what you’re working with and why each part matters in the overall functionality of your fan. Ready to start building? Let’s go!

Step 2: Preparing the Base

Alright, let’s get into the nitty-gritty of preparing the base of your DIY electric fan! The base is crucial as it provides stability and houses the motor that spins the fan blades. Here’s what you need to do:

Materials Needed:

- A sturdy piece of plywood or a plastic base

- A drill with screws

- Rubber feet (optional but recommended)

- Measuring tape

- A pencil for marking

First things first, take your plywood or plastic base and measure out a size that can comfortably hold your motor and support the fan. Typically, a square or rectangular piece of about 12 x 12 inches works well. Make sure it's thick enough to withstand vibrations.

Using your measuring tape, mark the positions where the motor will be fixed. This usually is at the center of your base. It’s important to make accurate measurements here, as any misalignment can cause imbalance in your fan. Drill holes in the marked spots, ensuring they align perfectly with the motor's mounting holes.

After that, secure the motor onto the base using screws. Don’t forget to add rubber feet! They can make a huge difference by reducing vibration and preventing the fan from sliding around. Just glue or screw them onto the corners.

Now, you should have a very sturdy base ready to go! This solid foundation is vital for the next step of the assembly. Excited? Let’s move on!

Step 3: Assembling the Fan Blades

Now for the fun part: assembling the fan blades! This is the step where we turn our attention to the component that actually creates airflow. Don't worry, it's easier than it sounds. Here's a breakdown of how to do this:

Materials Needed:

- Fan blade set (you can purchase these or make your own from a lightweight material like plastic)

- A hub to attach the blades to the motor

- Drill with screws

- Measuring tape

- Sandpaper (if you're making your own blades)

- Paint (optional, for aesthetics)

If you've purchased fan blades, great! If you opted to make your own, take your chosen material and cut it into blade shapes. A simple design is a rectangular or tapered shape. Remember to use sandpaper to smooth the edges, as this helps improve airflow.

Next, it's time to attach these blades to the hub. The hub is essentially the center piece that connects the blades to the motor. Ensure that the blades are evenly spaced and securely fixed so that they spin smoothly. Use screws to attach the blades to the hub firmly.

Once they’re all in place, you’re almost done! Consider giving them a splash of paint for a personal touch if you’re feeling creative.

And there you have it! Your fan blades should now be assembled and ready for their debut spin. Next up, we’ll be figuring out how to connect everything to ensure it runs like a dream!

Step 4: Installing the Motor

Now that you have your fan blades and frame ready, it’s time to bring the heart of your fan into the mix—the motor! This step is crucial because the motor is what gives the fan its life and ability to circulate air. Let’s dive into how you can install it effectively.

Before we get started, make sure you have your motor, screws, and any tools handy. Here’s a quick checklist of what you’ll need:

- Electric motor

- Screws or fasteners (usually included with the motor)

- Screwdriver (appropriate size for your screws)

- Mounting brackets (if not already built into the frame)

Follow these steps for a smooth installation:

- Positioning the Motor: Place the electric motor in the designated area on your frame. Ensure that it aligns with the fan blades as closely as possible for optimal performance.

- Secure the Motor: Using the screws or fasteners, attach the motor tightly to the frame. This ensures that vibrations are minimized when the fan is in operation.

- Double-Check Alignment: Before tightening everything down completely, check that the motor shaft is aligned with the center of the fan blades. Make any necessary adjustments.

- Secure Additional Components: If your motor has any additional components like a fan guard, ensure they are secured appropriately.

And there you have it! Your motor is now installed and ready for the next big step: wiring!

Step 5: Wiring and Safety Precautions

Now we’ve reached an important stage of your DIY electric fan project—wiring. Proper wiring ensures that your fan runs efficiently and safely, so pay close attention to these steps.

Before getting started, here’s what you’ll need:

- Wires (usually included with your motor)

- Wire cutters and strippers

- Electrical tape or heat shrink tubing

- Multimeter (to check connections)

- Safety goggles

Now, let’s go through the wiring process, along with some essential safety tips:

- Power Off: Always ensure your fan is unplugged while you’re working on it to avoid electrical shocks.

- Connect the Wires: Match the motor wires to the power source wires. Typically, you will connect the black wire (often the negative) to your power supply and the red wire (the positive) to its counterpart.

- Use Electrical Tape: Once the wires are connected, wrap them securely with electrical tape to prevent any exposed wires from causing short circuits.

- Test Connections: Using a multimeter, check your connections to ensure everything is wired correctly before plugging the fan in. This is critical for your safety!

Important Safety Precautions:

- Always wear safety goggles while working with electrical components.

- Check that your power source is suitable for your motor specifications.

- Never operate your fan without proper grounding.

With the wiring done safely, you’re just about ready to take your DIY fan for a spin! Just remember to double-check everything one last time before you connect it to power.

Step 6: Testing Your Electric Fan

Now that you’ve put your electric fan together, it's time to see if all your hard work has paid off! Testing your fan is crucial to ensure it operates safely and efficiently. Here’s a simple, step-by-step approach to testing your fan.

- Check Connections: Before plugging in your fan, double-check all your connections. Ensure that the wires are securely attached and that there are no exposed wires that could pose a safety hazard.

- Select Power Source: Use a suitable power outlet for testing. Make sure your outlet is rated for the voltage your fan requires—usually around 120V in North America, or 230V in many other countries.

- Plug It In: Once all connections are in place and everything looks good, plug your fan into the outlet cautiously. It’s a good idea to have your hands away from the blades and electrical components as you do this.

- Switch It On: Turn your fan on. Start with low settings to see how it performs. If all goes well, gradually increase to higher speeds.

- Listen for Sounds: Pay attention to any unusual noises. A proper fan should run fairly quietly, so if you hear grinding, buzzing, or rattling, it's worth troubleshooting further.

- Measure Airflow: Stand in front of the fan and gauge its airflow. You can even use a handheld anemometer if you want an exact measurement!

- Inspect Again: After testing, inspect for any overheating parts. If something feels too hot to touch, it’s best to disconnect and reassess the connections.

By following these steps, you can ensure that your fan is not only operational but also safe to use. Don’t rush this part—it's essential for your safety!

Conclusion

Congratulations! You’ve successfully built your very own electric fan. This DIY project is not just rewarding; it’s also a fantastic way to learn about electrical components and how they work together. Whether you need that refreshing breeze during hot summer days or just enjoy the satisfaction of building something from scratch, your new electric fan is sure to give you both!

Here’s a quick recap of what we’ve covered:

- Choosing the right materials is crucial to ensure functionality.

- Following a systematic approach helps to avoid mistakes.

- Testing your fan is essential for safety and efficiency.

Remember, DIY projects are all about exploration and learning, so don’t hesitate to experiment and modify your design to better suit your needs. If you encounter any hiccups along the way, look for online troubleshooting guides, and don’t hesitate to engage with communities who share your interest in DIY electronics.

Now, whether you use your fan at home, in the workshop, or give it away as a unique gift, you can take pride in knowing you built it yourself. So, go ahead and enjoy the breeze!