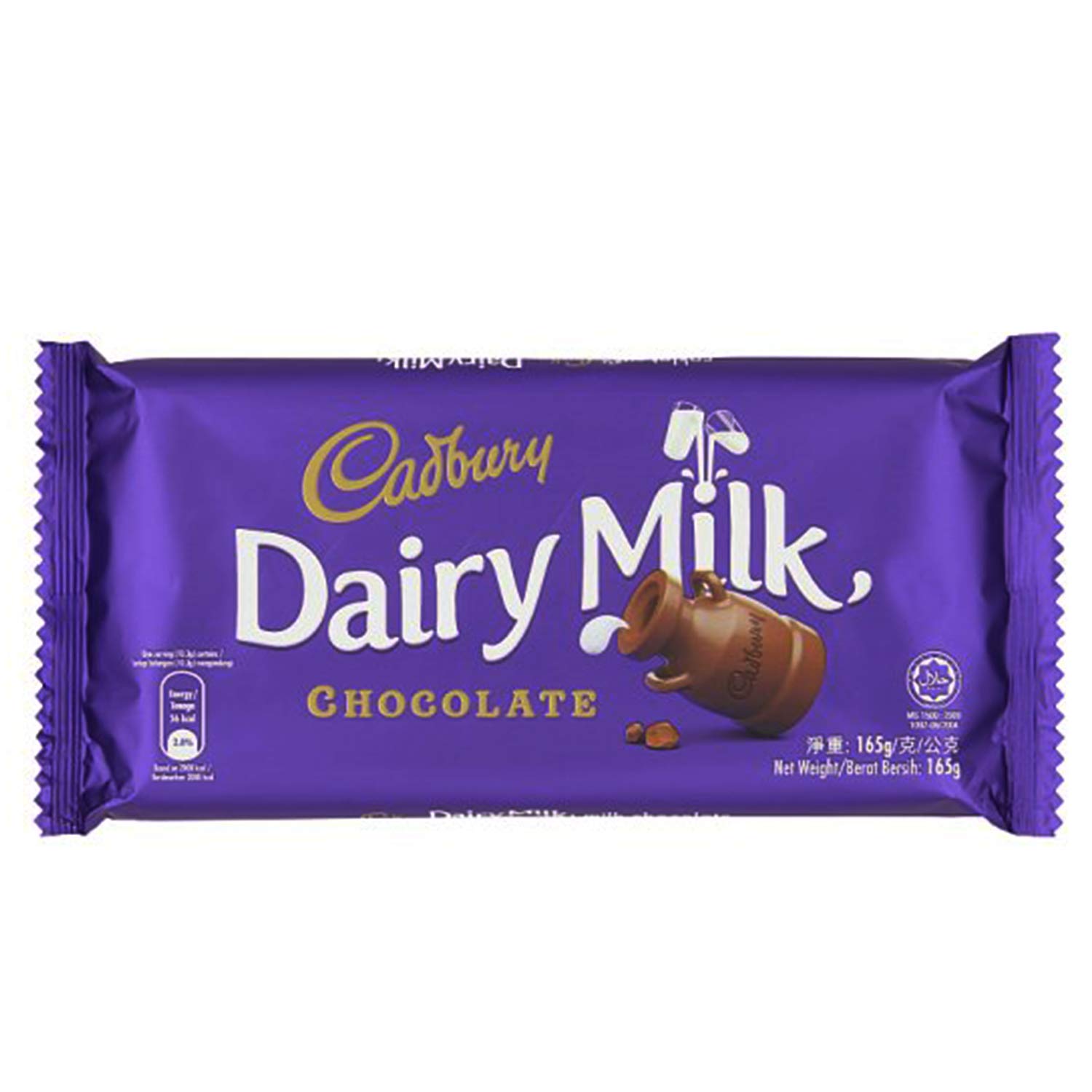

Dairy Milk Chocolate is a beloved treat that has captured the hearts of chocolate lovers all around the world. Known for its creamy texture and rich flavor, Dairy Milk offers a delectable experience that is hard to resist. This chocolate brand, created by Cadbury, has become synonymous with quality and indulgence. From its humble beginnings to its global recognition, Dairy Milk Chocolate holds a special place in many people's lives, evoking fond memories of childhood and sweet celebrations.

The Ingredients of Dairy Milk Chocolate

At the core of Dairy Milk Chocolate's delightful taste are its carefully selected ingredients. While recipes can vary slightly depending on the specific product, the primary components remain consistent. Here’s a closer look at what goes into creating this chocolatey goodness:

- Cocoa Solids: These are the non-fat components of cocoa beans and are fundamental for providing the rich chocolate flavor.

- Cocoa Butter: This is the fat extracted from cocoa beans, giving the chocolate its smooth texture and mouthfeel.

- Milk Powder: One of the key ingredients that sets Dairy Milk apart, milk powder adds a creamy flavor and enhances the chocolate’s richness.

- Sugar: Sweetness is essential, and sugar balances the natural bitterness of cocoa solids. It’s a crucial factor in making chocolate appealing.

- Lecithin: Used as an emulsifier, lecithin helps blend cocoa butter, cocoa solids, and milk powder, ensuring a uniform texture.

- Flavoring: Sometimes, a touch of vanilla or other flavors is added to enhance the overall taste.

To put it all together, here’s a simplified table of these ingredients:

| Ingredient | Purpose |

|---|---|

| Cocoa Solids | Adds chocolate flavor |

| Cocoa Butter | Provides smooth texture |

| Milk Powder | Contributes creaminess |

| Sugar | Adds sweetness |

| Lecithin | Acts as an emulsifier |

| Flavoring | Enhances taste |

Understanding these ingredients helps us appreciate the unique profile of Dairy Milk Chocolate, making each bite a delightful experience. So the next time you savor a piece, you'll know exactly what makes it so irresistible!

Also Read This: Rewards Redemption: Redeeming Amazon Gift Card from Microsoft Rewards

The Chocolate-Making Process

The journey of Dairy Milk chocolate from bean to bar is a fascinating one. It’s a blend of art and science that transforms humble cocoa beans into the creamy, delightful confection we all know and love. Let’s break down the chocolate-making process step by step!

1. Sourcing Cocoa Beans

Everything begins with the sourcing of high-quality cocoa beans. Major producers like Ivory Coast, Ghana, and Indonesia supply the beans. The quality of these beans is crucial, as it directly affects the flavor of the final product.

2. Fermentation

Once harvested, the cocoa beans undergo fermentation for about 5 to 7 days. This process, often done in shallow containers or beneath banana leaves, allows the beans to develop their rich chocolate flavor.

3. Drying

After fermentation, the beans are spread out under the sun to dry. This step is vital to reduce the moisture content and prevent spoilage. Dried beans can be stored for extended periods, allowing manufacturers to stock up.

4. Roasting

Next, the dried beans get roasted. This enhances the flavor and aroma. The temperature and duration of roasting can vary, impacting the final taste of the chocolate significantly.

5. Grinding

Once roasted, the beans are cracked open to remove the shell, leaving behind nibs. These nibs are ground into a paste called chocolate liquor, a mixture of cocoa solids and cocoa butter. This step is where the magic begins!

6. Conching and Tempering

In this stage, the chocolate liquor is further refined by conching, which creates a smoother texture. Tempering is then done to stabilize the cocoa butter crystals, giving the chocolate its shiny appearance and snap.

7. Molding and Packaging

Finally, the tempered chocolate is poured into molds, cooled, and then packaged for consumers. And just like that, the Dairy Milk chocolate you crave is created!

Also Read This: Downloading Music from YouTube to iPhone

Quality Control in Chocolate Production

Quality control is an essential component of chocolate production. It ensures that every bar of Dairy Milk chocolate meets high standards, giving customers a consistent and delightful experience. Here’s how quality control plays a pivotal role in this process:

1. Sourcing Quality Ingredients

Before anything is produced, the choice of cocoa beans, milk powder, and sugar must meet strict quality standards. Suppliers are regularly assessed to ensure they adhere to ethical farming practices and provide beans free from defects.

2. Sensory Evaluation

Tasting is a key part of quality control. Chocolatiers often conduct sensory evaluations to ensure the flavor, aroma, and texture of the chocolate meet the brand’s standards. During these sessions, they look for:

- Flavor balance

- Aromatic notes

- Texture consistency

3. Visual Inspection

Each batch of chocolate is visually inspected for any imperfections. This includes checking for:

- Shine and gloss

- Uniformity in color

- Surface irregularities

4. Testing for Composition

In the lab, chocolate samples undergo rigorous chemical analysis to ensure they meet nutritional specifications. This includes testing for sugar levels, cocoa content, and adherence to food safety standards.

5. Manufacturing Processes

During production, constant monitoring of temperatures and times ensures chocolate is produced uniformly. This helps prevent issues that could arise from overheating or improperly mixed ingredients.

6. Feedback Loop

Finally, customer feedback plays a critical role in the quality control process. Brands encourage consumers to share their experiences to improve future batches. Continuous improvement is key in maintaining the high quality associated with Dairy Milk chocolate.

In conclusion, the meticulous attention to detail in both the chocolate-making process and quality control ensures that Dairy Milk chocolate remains a beloved treat for chocolate lovers around the world!

Also Read This: Cross-App Melodies: Repeating a Song on SoundCloud – A Continuous Looping Experience

Sustainability Practices in the Dairy Milk Chocolate Industry

The dairy milk chocolate industry is making strides toward sustainability, understanding that its practices have significant impacts on the environment. Many companies are implementing various initiatives to reduce their carbon footprint, promote responsible sourcing, and support local communities. Let’s dive into some key sustainability practices in this sector.

- Ethical Sourcing: Major companies are focusing on sourcing cocoa from sustainable farms that adhere to ethical labor practices. This means better treatment and fair wages for farmers and their communities.

- Reducing Carbon Emissions: Many chocolatiers are investing in renewable energy sources and optimizing their production processes to minimize greenhouse gas emissions. For instance, some brands are moving towards solar or wind energy to power their production facilities.

- Waste Management: Effective waste management systems are being adopted to ensure minimal waste is generated during production. Whether it's composting organic waste or recycling packaging materials, every little bit adds up.

- Water Conservation: Water is an essential resource in chocolate production. Companies are implementing practices to reduce water usage, such as using advanced technologies that recycle water in the production process.

- Community Support: Many brands are investing in community development projects in cocoa-growing regions. This includes education programs, health initiatives, and economic support, ensuring that farmers and their communities thrive.

These sustainability practices not only help in preserving the environment but also enhance the quality of life for cocoa farmers and their families, contributing to a healthier ecosystem all around.

Conclusion and Final Thoughts

In conclusion, the journey of dairy milk chocolate from farm to bar is quite fascinating! As we’ve explored, it involves intricate processes including sourcing quality ingredients, precise manufacturing, and rigorous quality control. However, what's essential today is that the industry acknowledges its responsibility towards sustainability.

As consumers grow increasingly conscious of their choices, the demand for ethically produced chocolate is rising. Here are a few takeaways:

| Key Points | Benefits |

|---|---|

| Sustainable Sourcing | Supports local communities and encourages fair trade practices. |

| Environmental Responsibility | Helps in reducing the carbon footprint and conserves natural resources. |

| Consumer Awareness | Informs consumers about the importance of choosing sustainable products. |

As you indulge in a piece of dairy milk chocolate, remember that your choice is more than just a treat; it’s an opportunity to support a movement towards sustainable practices. Every small decision can lead to significant change, and the chocolate industry is waking up to this reality. So, take a moment to appreciate not just the deliciousness, but also the effort that goes into making your favorite chocolate bar!

admin

admin