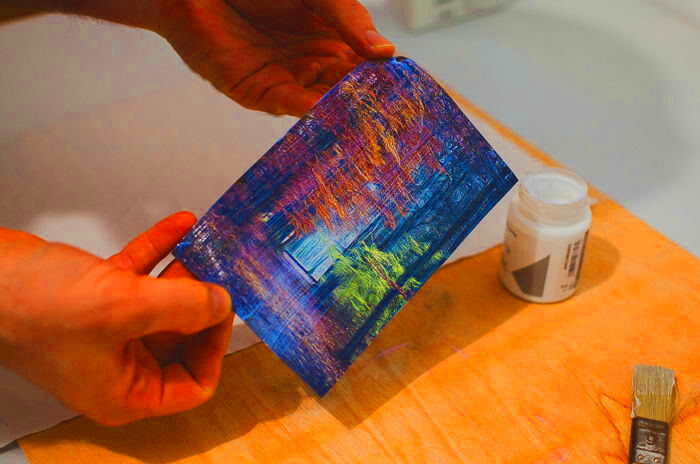

Transferring images to fabric is a fun and creative way to personalize items like t-shirts, bags, pillows, and quilts. Whether you're making custom gifts or starting a DIY project, the process can seem tricky at first. But with the right tools and a little practice, you can easily transfer high-quality images onto fabric and make your designs come to life. In this section, we'll explore the basics of image transfer, including what you need and how the process works. Let's dive in!

Understanding the Different Methods of Image Transfer

There are several methods available for transferring images to fabric, each with its own unique advantages and challenges. Below, we’ll discuss the most popular methods used for fabric image transfer:

- Heat Transfer Paper: This is one of the most common methods. You print your image on heat transfer paper, then use an iron or heat press to transfer the image onto fabric.

- Printable Fabric Sheets: These special sheets are designed to go through your printer. Once printed, the fabric can be sewn or ironed onto your project.

- Iron-On Transfers: This is similar to heat transfer paper but often involves pre-designed sheets. Simply peel off the backing and iron the image onto your fabric.

- Sublimation Printing: This technique involves using heat to transfer dye directly onto fabric, ideal for polyester or polyester-coated fabrics.

Each method has its ideal use depending on the fabric, the type of design, and the desired outcome. It’s important to choose the right technique to ensure your image transfers correctly and lasts long. Experimenting with these methods can help you figure out which one works best for your projects.

Choosing the Right Image for Fabric Transfer

The type of image you choose plays a significant role in how well it will transfer to fabric. Here are some key considerations when selecting an image:

- Resolution: High-resolution images (300 dpi or higher) ensure the final print is sharp and clear. Low-resolution images may appear pixelated once transferred.

- Color Scheme: Choose images with bold, contrasting colors for the best results. Light or pastel colors may not show up as well, especially on light-colored fabrics.

- Design Complexity: Simple designs or graphics with clean lines are easier to transfer. Highly detailed or intricate designs may not come out as clearly on fabric.

- Image Format: Use file formats like PNG or JPEG that maintain the quality of your image. Avoid files with too much compression or excessive artifacts.

Before starting, it’s also a good idea to print a test version of your image on paper to see how it looks. This will give you a better idea of how the design will appear once transferred to fabric. Avoid overly large designs for smaller fabrics, as they might become distorted or lose clarity.

Preparing the Fabric for Image Transfer

Before you can transfer an image onto fabric, it’s crucial to properly prepare the fabric to ensure a smooth, successful transfer. Preparing the fabric properly will help the image adhere better and last longer. In this section, we’ll discuss some important steps to take before starting the transfer process.

Here’s how to prepare your fabric:

- Choose the Right Fabric: Cotton, linen, and polyester blends are great options for fabric transfers. Avoid fabrics with too much stretch or slippery surfaces, as they can make the transfer process more challenging.

- Wash the Fabric: Always wash the fabric before you start. This removes any chemicals, dust, or oils that might interfere with the transfer. Skip the fabric softener as it can leave a coating that prevents the image from sticking.

- Iron the Fabric: After washing, make sure the fabric is wrinkle-free. Iron it to smooth out any creases. Wrinkles can distort the image during the transfer, so it's best to get your fabric as flat as possible.

- Trim the Edges: If you're working with a pre-cut piece of fabric, trim the edges to remove any frayed or uneven areas. This ensures a clean area for the transfer.

Once your fabric is prepared, you’re ready to start the image transfer process. Proper preparation helps guarantee that the image will transfer clearly, and your final project will have a professional look. Keep in mind that the fabric needs to be dry and clean for the transfer to work successfully.

Steps for Using Heat Transfer Paper

Heat transfer paper is one of the most popular methods for transferring images to fabric. It's simple to use, affordable, and gives great results. Below are the steps to help you achieve the best results when using heat transfer paper:

- Select the Right Heat Transfer Paper: Choose a heat transfer paper that’s suitable for your fabric type (light or dark). Make sure you buy the right paper for your printer (inkjet or laser).

- Print Your Image: Load the heat transfer paper into your printer, ensuring that the image is mirrored (flipped horizontally). This is important because the image will be reversed when transferred to the fabric.

- Prepare the Fabric: As mentioned earlier, wash and iron the fabric to remove any wrinkles or residues. Lay it flat on a heat-resistant surface like a wooden table or heat press pad.

- Place the Transfer Paper on Fabric: Position the printed transfer paper onto the fabric with the image facing down. Be sure it’s centered, and avoid wrinkles.

- Apply Heat: Use an iron or heat press. If you're using an iron, set it to a high cotton setting (without steam). Press down firmly and move the iron slowly in a circular motion for the time recommended by the paper manufacturer (usually 30 seconds to 1 minute).

- Peel the Paper: Once the transfer has cooled for a few minutes, carefully peel off the paper. Make sure the image has fully adhered to the fabric. If necessary, apply additional heat and repeat the process.

Heat transfer paper works best for simple designs, text, or images that don’t require too much detail. It’s a fast and effective way to get professional-looking results without a lot of fuss.

How to Use Printable Fabrics for Image Transfer

Printable fabrics are a fantastic option for transferring images, especially if you want to print directly onto fabric. This method eliminates the need for heat transfer paper and works well with both inkjet and laser printers. Here’s how you can use printable fabrics to transfer images:

- Choose Printable Fabric: Printable fabrics come in various forms, such as fabric sheets that are coated for inkjet or laser printers. Ensure you select the right type for your printer. Some printable fabrics are designed for quilting or for use in embroidery machines.

- Print Your Image: Load the printable fabric sheet into your printer, just as you would with regular paper. Be sure the fabric is loaded correctly so the image prints on the fabric side. Ensure your design is properly sized for the fabric sheet.

- Prepare the Fabric: Like with heat transfer paper, it’s important to wash and iron your fabric before printing. This ensures that the fabric is free from any impurities that could affect the printing process.

- Print the Image: Once the fabric is ready, print the image using your printer’s highest quality setting. Make sure your image is properly aligned and that the printer settings are optimized for fabric.

- Set the Ink: After printing, it’s often necessary to set the ink. This can be done by ironing the fabric on the reverse side to ensure the ink is heat-fixed and will not wash out easily. Follow the manufacturer’s instructions for this step.

- Attach the Fabric to Your Project: After the image is printed and the ink is set, you can use the fabric in your sewing or crafting project. Whether you’re making a pillowcase, quilt, or custom garment, this printable fabric method provides a flexible, high-quality result.

Printable fabrics work especially well for detailed images and are a great choice if you want more intricate designs or higher color accuracy. Just keep in mind that the fabric may need to be treated to ensure the ink stays vibrant after washing.

Common Mistakes to Avoid While Transferring Images to Fabric

Transferring images to fabric is a fun process, but it's easy to make mistakes along the way, especially if you're new to it. These mistakes can affect the final result, so it’s important to be aware of them. In this section, we’ll highlight some common mistakes and how to avoid them.

- Using the Wrong Type of Fabric: Not all fabrics are suitable for image transfers. Fabrics with too much stretch or a slippery surface can make the transfer process difficult. Always choose cotton, linen, or polyester for the best results.

- Skipping Fabric Preparation: Failing to wash and iron the fabric before transferring can lead to poor results. Wrinkles, oils, and dirt can interfere with the transfer. Always ensure the fabric is clean, dry, and smooth.

- Incorrect Printer Settings: Using the wrong settings for your printer can affect the quality of the transfer. Make sure your printer is set to the highest quality and that the image is mirrored before printing for transfers using heat transfer paper.

- Not Testing the Transfer: It's always a good idea to test your transfer on a scrap piece of fabric first. This helps you adjust the heat and pressure for optimal results and prevents mistakes on your final project.

- Overheating the Fabric: Using too much heat can damage the fabric or cause the image to burn or blur. Always follow the recommended temperature and timing for your chosen transfer method.

- Not Allowing the Transfer to Cool Properly: Removing the transfer paper or fabric too soon can cause the image to smudge. Let it cool down for a few minutes before peeling off the transfer paper.

Avoiding these common mistakes will help ensure that your image transfer turns out just the way you want. Take your time, follow the steps carefully, and you’ll get great results.

How to Care for Fabric After Image Transfer

Once you've successfully transferred an image to fabric, it’s important to take good care of it to ensure the image lasts as long as possible. Whether it’s a custom t-shirt, a pillow, or any other fabric item, proper care will keep your image looking fresh and vibrant. Here are some tips for maintaining fabric with transferred images:

- Wash with Care: Always turn your fabric inside out before washing it. This helps protect the image from friction and wear. Use a gentle cycle with cold water to prevent fading or damage to the transfer.

- Avoid Fabric Softener: Fabric softeners can leave a coating on the fabric that affects the image. Skip the softener, as it can make the transfer less durable.

- Avoid High Heat: When drying the fabric, avoid high heat. Opt for air drying or tumble dry on a low heat setting to prevent the image from peeling or cracking over time.

- Iron Carefully: If you need to iron the fabric, do so carefully. Use the reverse side of the fabric, and place a cloth between the iron and the image to avoid direct contact with the transfer. This will prevent the image from melting or becoming distorted.

- Store Properly: When not in use, store your fabric items in a cool, dry place. Avoid folding or creasing areas with the image, as this could lead to cracks or peeling over time.

By following these simple care tips, you can ensure that your transferred images stay intact and vibrant for a long time. Proper maintenance is key to extending the life of your fabric projects.

FAQ

In this section, we answer some of the most common questions people have about transferring images to fabric. If you’re new to this process or want to improve your technique, the answers below can help.

- Can I use regular printer paper for fabric transfers? No, regular printer paper isn’t designed for fabric transfers. You'll need special heat transfer paper or printable fabric sheets that are specifically made for this purpose.

- Do I need a special printer for transferring images to fabric? It depends on the method you're using. Most fabric transfer methods can be done with a regular inkjet or laser printer, but ensure that you choose the right paper or fabric sheets that match your printer type.

- Can I transfer images to dark fabrics? Yes, but you'll need to use transfer paper specifically designed for dark fabrics. This paper is usually opaque and will help the image show up clearly against dark backgrounds.

- How long will the transferred image last? The longevity of the image depends on the quality of the transfer method and how well you care for the fabric. With proper care, the image can last for a long time, even after multiple washes.

- Can I transfer photos to fabric? Yes, photos can be transferred to fabric, but it's important to use high-resolution images and follow the appropriate transfer method. Photos with too much detail may not transfer well, so simpler images or higher contrast designs tend to work better.

If you have any more questions or run into issues, don’t hesitate to do further research or try experimenting with different transfer methods. Every project is a learning experience!

Conclusion

Transferring images to fabric is a rewarding and creative process that can elevate your DIY projects, whether you're making personalized gifts, home decor, or custom clothing. By choosing the right fabric, preparing it properly, and using the best transfer methods, you can ensure your designs look great and last for a long time. Avoid common mistakes like skipping fabric preparation or using the wrong materials, and always take good care of your transferred fabric to preserve its vibrancy. With the tips and techniques shared in this guide, you’re ready to start experimenting and creating your own fabric masterpieces!